Expanding intumescent technology prevents flames from spreading through ventilated cavities

Wilmington, DE – June 9, 2023 – In response to the adoption of the 2022 Building Code by New York City, Tenmat, a leading manufacturer of advanced firestopping materials and solutions, has partnered with 3A Composites USA, the global manufacturer of ALUCOBOND® PLUS 4mm aluminum composite material (ACM) to conduct a joint NFPA 285 fire test.

Together, the companies performed a groundbreaking NFPA 285 fire test at Intertek Laboratories, leveraging the expertise of Tenmat’s FF102/50 fire block and highly regarded ALUCOBOND to meet the rigorous new regulations of the building code.

The newly adopted code requires fire blocking within rainscreen assemblies, if combustible materials are used within the wall assembly. With testing complete, the architectural community has more cladding options to choose from without increasing assembly costs. For decades, ALUCOBOND has been a dominant cladding of choice around the world due to its formability and flatness allowing custom facades and freedom of design. “We are excited to provide a constructible and cost-effective solution that allows the architectural community to continue using ALUCOBOND to bring their vision to life.”, stated Nick Scheib, general manager at 3A Composites. “This joint effort between Tenmat and 3A Composites represents our commitment in providing solutions for the marketplace.”

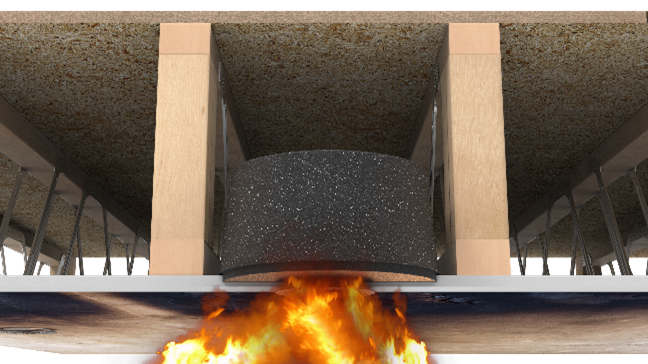

In response, Tenmat has developed a quick acting intumescent fire block for ventilated rainscreen and cladding systems, the FF102/50. The innovative FF102/50 fire blocks are designed to allow the practical benefits of cladding systems, such as energy conservation, air circulation, and moisture dissipation, while meeting the new code requirements.

Tenmat’s FF102/50 employs state-of-the-art intumescent technology that expands 25 times its original thickness when exposed to fire, effectively counteracting the adverse consequences of the concealed space behind the cladding.

Minutes to Install, Permanent Peace of Mind

This successful NFPA285 test is one of the first of its kind to be specifically designed and installed in accordance with the new stringent requirements of the 2022 New York City Building Code. The FF102/50 fire block was expertly deployed around window openings and at all slab lines, meticulously adhering to the position requirements for fire blocking material in the updated building code. Under normal conditions, Tenmat’s rigid and highly expansive intumescent fire block enables the maintenance of an open ventilated cavity, preserving the energy conservation and building science benefits associated with cladding systems, while concurrently serving as a formidable fire barrier in the event of a building fire. With the successful completion of the NFPA 285 test, validating the performance of Tenmat’s FF102/50 and 3A Composites’ 4mm fire retardant ALUCOBOND® PLUS both companies are and envision a construction landscape in New York City where passive fire protection standards are enhanced.

About Tenmat

For over 100 years, Tenmat has been a leader in the development, engineering and manufacturing of intumescent materials that offer advanced passive fire protection and fire blocking capabilities.

Tenmat offers a unique range of flexible, lightweight, and ready-to-use products and solutions for the most demanding firestopping applications. Our state-of-the-art, in-house R&D Laboratory and ISO 9001:2015 accredited production facilities have been developing and manufacturing technically superior passive fire protection products and intumescent materials for over 100 years. All Tenmat products have been fire tested by independent third-party labs such as UL and Intertek.

Tenmat USA is headquartered in Wilmington, DE. For further information about Tenmat and our line of innovative firestopping materials and solutions, please call 1-800-821-3436, email info@tenmatusa.com or visit www.tenmatusa.com.

About 3A Composites

3A Composites is a leading producer of materials for the metal facades market. Since 1969, the company has been developing, manufacturing and marketing high-quality aluminum composite panels, structural composite material, plastic sheets and lightweight foam boards for the architecture, visual communication and transport and commercial building industries.

3A Composites is part of the international 3A Composites Group, which belongs to the listed company Schweiter Technologies headquartered in Horgen, Switzerland. Visit https://www.3acomposites.com for details.

The 3A Composites USA headquarters are located in Davidson, N.C. U.S.-based manufacturing facilities are located in Benton, KY, where they produce ALUCOBOND, used in the architectural and building cladding industries for over 50 years. For more information about ALUCOBOND PLUS, ALUCOBOND AXCENT, and ALUCOBOND EasyFix call 1-800-626-3365, email info.usa@3AComposites.com or visit www.alucobondUSA.com.