Discover how properly fire-rated through-penetration openings play a pivotal role in protecting our current and future communities.

Passive Fire Protection in Modern Construction

“Are these ceiling openings properly fire rated?” “Do I need a one-hour or two-hour fire rating for this recessed can light?” “Are you installing intumescent material into your ventilated rainscreen system?” Over the past several construction seasons, these various questions have been asked on active job sites and in planning rooms: however, all of these questions circle back to one popular topic – passive fire protection. With its prominent impact on life safety, passive fire protection has overtaken the construction landscape by storm – especially with unprotected openings. Often, we associate unprotected openings within ceiling assemblies, which have been penetrated by recessed can lights, LED downlights, troffer luminaires and/or in-ceiling loudspeakers. However, let’s think smaller. Let’s talk about through-penetration openings in fire-resistance rated assemblies.

Thinking it “Through”ly.

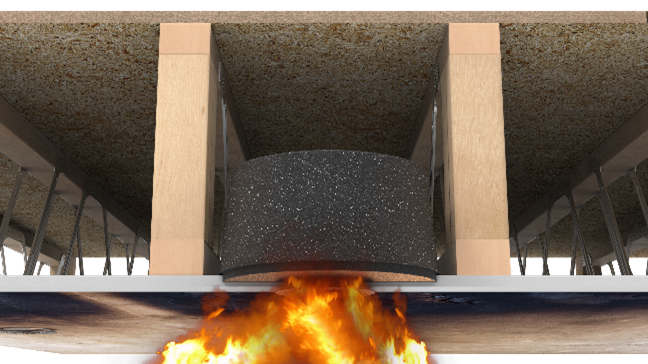

With the surge of technology, new construction infrastructures are home to hundreds of running wires, cables, and pipes running through the wall, ceilings, and walls of these buildings. As a result, when these fire-resistance rated assemblies are penetrated by one of these elements, the assembly is compromised – regardless of how small the magnitude of the opening. Even though these penetrations tend be relatively small, it still creates a pathway for heat, smoke, and flames to rapidly consume the infrastructure of the building. As a response to this life safety hazard, the IBC (International Building Code) regulated that proper firestopping measures are required for through-penetration applications. For a reference, in Section 714.3.1.2 of the 2012 IBC, it states,

“Through penetrations shall be protected by an approved penetration firestop system installed as tested in accordance with ASTM E814 or UL 1479, with a minimum positive pressure differential of 0.01 inch (2.49 Pa) of water and shall have an F rating of not less than the required fire-resistance rating of the wall penetrated.”

Identifying Where Proper Firestopping is Required.

As this building code adapts to the modern construction scene, it is critical to educate construction professionals on where this code will apply. With 100% of US buildings containing at least one wire, cable, or pipe – this requirement is universal. However, here are some common construction practices that will potentially require firestopping solutions for through-penetration openings:

- Multi-Family

- Data Storage Facilities

- Modular

- Façades

- Healthcare (Hospitals, Rehabilitation Centers, Medical Centers)

- Hospitality

- Commercial

- Industrial

Tried, Trusted, Tested, Through-Penetration with Tenmat.

With our commitment to protect the lives and property of our current and future communities, Tenmat has designed a full line of firestopping solutions for through-penetration openings. All of Tenmat’s Firestopping Solutions and Materials are accurately assessed and certified at third-party testing laboratories, such as Underwriter Laboratories (UL) and Intertek (ETL). To learn more about Tenmat’s Firestopping Solutions for Through-Penetration Systems, please continue reading below!

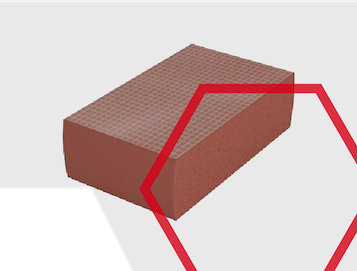

FF260 Fire Protection Block

Formulated to protect openings caused by cables, pipes, or mixed penetrations, the FF260 Fire Protection Block is an optimal solution for a majority of through penetration systems. Composed of a rapidly expanding intumescent foam, the FF260 is able to halt the spread of flames, heat, and smoke for up to 120 minutes. To learn more about this solution, please click here!

Formulated to protect openings caused by cables, pipes, or mixed penetrations, the FF260 Fire Protection Block is an optimal solution for a majority of through penetration systems. Composed of a rapidly expanding intumescent foam, the FF260 is able to halt the spread of flames, heat, and smoke for up to 120 minutes. To learn more about this solution, please click here!

Key Benefits Include:

- 120-minute fire protection

- Easy retroactive installation

- UL Classified

FF360 Fire Protection Foam

UL-Classified. Properly fire rates membrane penetrations in walls and ceiling assemblies. Designed for irregular, hard-to-access, and large penetrations. Meet the FF360 Fire Protection Foam. Tenmat’s FF360 Fire Protection Foam is the optimal firestopping solution for through-penetration applications, due to its composition flexibility, hassle-free installation and proper testing certification for up to 120 minutes. Interested in learning more about this advanced intumescent product, click here.

UL-Classified. Properly fire rates membrane penetrations in walls and ceiling assemblies. Designed for irregular, hard-to-access, and large penetrations. Meet the FF360 Fire Protection Foam. Tenmat’s FF360 Fire Protection Foam is the optimal firestopping solution for through-penetration applications, due to its composition flexibility, hassle-free installation and proper testing certification for up to 120 minutes. Interested in learning more about this advanced intumescent product, click here.

Key Benefits Include:

- 120-minute fire protection

- Quick Curing Formulation – Offers clean application and strong adhesion.

- Easy Retroactive Composition – Allows for additional wires, cables, and pipes post-installation.

FF365 Fire Protection Sealant

Trying to properly fire rate a small, irregular penetration opening? At Tenmat, we offer a specialized firestopping solution, designed to fire-rate the most irregular and smallest openings, and composed of the latest in intumescent technology. Tenmat’s FF365 Fire Protection Sealant is a red, one-component, gun-grade, intumescent firestop sealant for use in a variety of UL through-penetration firestopping. In addition to its firestopping abilities, the FF365 can be used in combination with other TENMAT products, such as the FF260 Fire Protection Block. To learn about the true capabilities of this fire-rated solution, please click here.

Trying to properly fire rate a small, irregular penetration opening? At Tenmat, we offer a specialized firestopping solution, designed to fire-rate the most irregular and smallest openings, and composed of the latest in intumescent technology. Tenmat’s FF365 Fire Protection Sealant is a red, one-component, gun-grade, intumescent firestop sealant for use in a variety of UL through-penetration firestopping. In addition to its firestopping abilities, the FF365 can be used in combination with other TENMAT products, such as the FF260 Fire Protection Block. To learn about the true capabilities of this fire-rated solution, please click here.

Key Benefits Include:

-

- 120-minute fire protection

- Easy Application with Conventional Caulking Equipment

- Adapatibility to fill unprotected openings, regardless of size, shape, and depth.

Take Action.

In the great words of Benjamin Frankin, he stated “A small leak can sink a great ship” – just like how a small, unprotected penetration opening can destroy an entire infrastructure. By properly specifying passive fire protection in through-penetration applications, you are taking the steps to protect our communities from the “scorching” consequences of rapidly evolving fire outbreak. If this article didn’t answer all your questions about passive fire protection for through-penetration systems, please feel free to contact one of our on-site specialists at +1-800-821-3436 or email us at info@tenmatusa.com.