Installing intumescent materials for fire safety.

Intumescent products and materials have been in the market for several decades. An intumescent is a material which reacts and expands aggressively when exposed to heat or fire. Depending on the requirements of the application, the expansion rate can be up to 30 times the original size of the product. The pressure generated by the intumescent when expanding can be tailored for each application, but it can also easily crush plastic pipework. Once expanded, the intumescent product creates a tough and solid char, which can prevent the spread of fire, heat, and smoke for many hours.

Intumescent products have been a key component in applications such as fire door seals, pipe and penetration seals, and linear gap seals. Over the years, many of these products have been supplied to protect both buildings and their occupants, making them a trusted and widely approved firestop solution.

Intumescent products compared to traditional firestopping products

In the past, traditional firestopping products such as mineral fiber and sheet rock were the mainstay of the industry. When construction materials and practices were largely limited to just a few different options, they worked very well, as the basic construction materials—for example, brick and block—did not “move” much in the event of a fire. When a construction material does not “move” or deform in a fire, then a firestop which does not react can work perfectly well.

Today, buildings are constructed using a greater variety of materials, including masonry, timber, steel, metallic, and polymeric materials—all of which expand at different rates in a fire. Some degrade quickly, while others distort. When construction materials “move” in a fire situation, gaps are opened and shapes and sizes of penetrations change, which in turn, allow fire and smoke to pass through. In these situations, traditional firestop materials simply do not work well, as they do not respond to the changes taking place. In comparison, intumescent products react and expand to fill all the gaps and changes created by the fire, and therefore, can maintain a high-performance fire barrier for an extended duration. The key requirement of a good firestopping product is one which will fill, insulate, and seal all gaps in a building fire compartment as a fire develops and movement occurs.

Another reason for building movement is due to seismic activity. This often happens over time, before a fire occurs, and can cause gaps and cavities in the fire compartment to appear and grow in size. Traditional firestopping methods cannot usually seal such changes in construction, or they become dislodged or damaged, so the fire compartment is compromised long before any fire-related events. Intumescent firestopping products have been tested and shown to fill any large gaps and cavities present before a fire occurs.

A further benefit of intumescent products is their installation, which is generally simpler. Traditional firestops tend to require a great deal of skill and time to install correctly, as they often require combinations of both wet and dry processes. Intumescent products tend to be designed for the specific application, and the skilled parts of the product are incorporated at the factory in controlled conditions and not onsite.

Types of intumescent products

While it is a widely accepted opinion that intumescent products represent much safer solutions for many firestopping applications, it is not the whole story. All intumescent products are not created equally. Today’s products can be divided into two basic groups: dumb and smart intumescent materials.

Dumb intumescent materials

A dumb intumescent is typically a rubber-based material which is extruded or pressed into sheets, with no structure to the dispersion of the intumescent particles within the application. The main reason it is called “dumb” is because when it expands, it has no sense of direction and will expand in all directions equally. Additionally, if a random gap exists, it will flow through it as well, rather than in the direction required to stop the fire spread.

The only way to use such dumb intumescent materials successfully is to totally encase them in a fire-resistant canister or box, so the expansion can only occur in the direction required, and all other directions are sealed. A typical example of their use would be in fire collars, where the intumescent is contained within a steel shell around the pipe to direct the expansion inwards.

Another disadvantage of rubber-based intumescent is the high organic content, which means it creates a great deal of smoke in a fire situation—which can be dangerous for both occupants and firefighters alike.

Dumb intumescent materials are generally produced in high volume, with no particular design application in mind. These materials are then supplied to “convertors” who incorporate them into products, which must be encased, to make them work in the manner required.

Smart intumescent materials

Smart intumescent materials are very different because of the way they work. The materials are generally produced for a specific end application from the start of the production process. Smart intumescent materials can be fine-tuned to provide expansion in only the direction required for the application, and they can even be formed into the finished product shape.

Unlike other types of intumescent materials, smart ones do not use rubber as the basic matrix. Instead, they use mineral fibers, which are layered along with intumescent particles in the forming process to produce a multi-layered product. This structure allows accurate control of both the rate and direction of expansion.

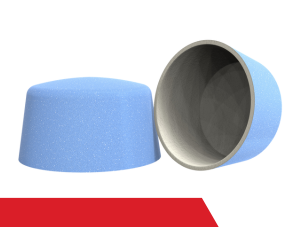

Vacuum forming allows complex 3D shapes to be created while having full control over the direction of expansion.

Since smart intumescent materials have their expansion rate and direction inherently controlled at the factory, they do not require the same levels of encasement as dumb products, meaning the finished product design can be simplified in many ways regarding weight, cost, and ease of installation.

Another benefit of smart intumescent materials is they tend to have very low organic content, mainly due to their structure being of mineral fibers and not rubber. As a result, they produce very low smoke in a fire. Some smart materials are even classified as “low smoke zero halogen,” which is good news for building occupants and firefighters.

Conclusion

Building materials and construction techniques have changed significantly in recent years, and the materials used to firestop these buildings have not kept pace with these changes. This has been unfortunately demonstrated by a number of high-profile building fires. Traditional firestopping simply cannot cope with the building movement which occurs in a modern building fire. Therefore, intumescent materials must be considered, as they offer the required advancements in firestopping technology. However, it is important to remember not all intumescent materials are the same, and smart intumescent options offer different benefits compared to dumb intumescent options.

The Solutions that Set the Standards – Meet the FF109-300 and FF109-350.

The Solutions that Set the Standards – Meet the FF109-300 and FF109-350. Pushing the Boundaries of Life Safety – Experience Tenmat’s FF109-X.

Pushing the Boundaries of Life Safety – Experience Tenmat’s FF109-X. Retrofit for a Perfect Fit – Presenting the FF109-200 and FF109-250.

Retrofit for a Perfect Fit – Presenting the FF109-200 and FF109-250. Fight the Flames, Protect the Sound Waves – Introducing the FF109-FRSC.

Fight the Flames, Protect the Sound Waves – Introducing the FF109-FRSC. Tested and Trusted Troffers: Meet the FF130 – 2’x2’ and FF130 – 2’x4’.

Tested and Trusted Troffers: Meet the FF130 – 2’x2’ and FF130 – 2’x4’. Fires in Façades: Introducing Tenmat’s FF102/50 Intumescent Fire Block.

Fires in Façades: Introducing Tenmat’s FF102/50 Intumescent Fire Block. “Plugging” Up the Flames: Meet Tenmat’s FF160 Fire Protection Plug.

“Plugging” Up the Flames: Meet Tenmat’s FF160 Fire Protection Plug. Fire“Blocking” At Its Finest: Presenting Tenmat’s FF260 Fire Protection Block.

Fire“Blocking” At Its Finest: Presenting Tenmat’s FF260 Fire Protection Block. Defending All Pathways, No Matter How Small – Discover Tenmat’s FF360 Fire Protection Foam.

Defending All Pathways, No Matter How Small – Discover Tenmat’s FF360 Fire Protection Foam. “Sealing” the Future with Life Safety – Featuring Tenmat’s FF365 Fire Protection Sealant.

“Sealing” the Future with Life Safety – Featuring Tenmat’s FF365 Fire Protection Sealant.