Explore the process of specifying appropriate passive fire protection solutions into active and future reconstruction projects.

Opening Up the Floor.

In the modern world of construction, we always discuss the latest practices and technological innovations for new construction – so, what about pre-existing buildings? From preserving historical structures to repurposing outdated buildings, redevelopment projects have become an increasing trend in the landscape. However, construction professionals are facing a huge challenge – specifying appropriate passive fire protection systems into these modernized infrastructures – especially when it comes to relighting renovations and audio additions.

To address this growing safety issue, Tenmat will be reviewing the following in this article:

- The purpose of implementing passive fire protection, and how it coordinates with previously installed active fire protection systems,

- Why passive fire protection is essential when renewing the lighting and/or audio systems in pre-existing buildings, and the

- Key strategies and common mistakes that arise when specifying passive fire protection in ceiling upgrades and renovations.

By examining the purpose, benefits, and key strategies of specifying passive fire protection, this discussion aims to equip construction professionals with the insights needed to enhance safety and efficiency in relighting renovations and beyond. Let’s dive into the essential considerations that will allow our present and future buildings to provide true peace of mind for their occupants.

Understanding the Balance of Passive and Active.

Often, when curating the plans and specifications for new construction projects, architectural engineers ensure all 1) building code regulations are properly met, and 2) the appropriate technology and/or solutions are accurately installed. However, if you are a member of the construction landscape, you understand the turnaround of amending building regulations – an almost everyday occurrence. Therefore, it is fairly common that when remodeling a pre-existing building, parts of the structure aren’t aligned with the current version of the building code. Due to this typical complication, the project’s construction team will need to update the structure to meet the current building code requirements – especially when it comes to life safety.

Regardless of whether you are standing present-day in a late 19th century or 21st century building, you will be able to easily detect standard, updated active fire protection systems, such as fire sprinkler systems and fire extinguishers. On the other hand, the rapid adoption of various passive fire protection requirements creates a high level of difficulty for recently built infrastructures to even meet the most up-to-date code. Therefore, it is critical to ensure that these passive fire protection systems are updated properly when a pre-existing building is experiencing a remodel.

Why Does It Matter.

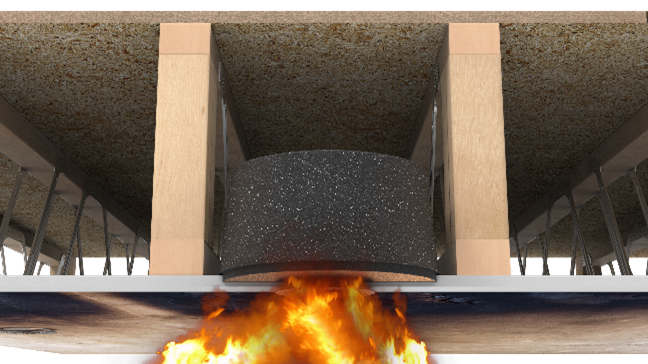

Why? Well, it resides with one the main reasons on why we specify passive fire protection systems in the first place – the safety of lives and property. Often, during remodeling projects, a variety of violations of the fire code arise; however, there is one single safety issue that flies under the radar– unprotected ceiling openings. Intermittently, architects and developers tend to be unfamiliar with or overlook Section 714.5.2 of the 2021 IBC, which addresses the significance of properly fire rating unprotected ceiling openings. When installed into a fire-resistance rated ceiling/floor assembly, recessed ceiling fixtures, whether it be a lighting or audio, allows a clear pathway for an active fire to travel. When exposed to the high temperatures of a fire for several minutes, the ceiling fixture is reduced to nothing – allowing heat, flames, and smoke to rapidly accelerate throughout a building.

To tackle this life safety hazard, modern day architects have begun specifying proper passive fire protection measures to certify that these openings are sealed properly, and the assembly’s integrity is reinstated. Alas, this reinstatement process has only been regulated into modern-day construction – which opens the concern surrounding relighting renovations in prior existing infrastructures. In these relighting projects, contractors are being faced with the task to reinforce the ceiling’s unprotected openings. So, how would a contractor go about rectifying this life safety hazard?

Key Tools to Successful Relighting Projects.

When determining your initial steps to confirm the integrity of your fire-rated ceiling, you need to detect if your ceiling needs to be properly fire-rated. As previously stated, it is common for contractors to not recognize the demand for passive fire protection for in-ceiling fixtures – especially if there isn’t any current passive fire protection present. Therefore, it is extremely critical to review your project’s plan and the International Building Code to determine if your relighting project will need a proper passive fire protection system. After this determination, it is critical to select the most appropriate fire-rated solution for the project itself. To name some of criteria to ponder in this selection is:

- Does the fire-rated solution align with the stringent building code requirements in the Internation Building Code?

- Has the fire-rated solution been properly tested and certified by an accredited third-party laboratory?

- Will the installation of this solution meet the project’s personal demands, such as expected lead times and retrofitting demands?

When deciding on which fire-rated solution you will specify into your project, it is important to recognize if the solution can be installed into a pre-existing ceiling. Majority of fire-rated solutions, such as traditional fire-rated drywall boxes, are unable to installed into a pre-existing ceiling – adding major delays in project lead times and astronomical labor costs. Here at Tenmat, we have acknowledged these universal complications and have designed a line of fire-rated solutions to meet not only the building code; but, the demand of the individuals, who will be specifying and installing these solutions. Explore the benefits of choosing Tenmat’s Fire Rated Covers for relighting upgrades in pre-existing ceilings below:

Passive Fire Protection for Recessed Lighting Fixtures.

- Universally, pre-existing buildings are looking to decrease their monthly energy costs – opting in for energy-efficient light fixtures. Some of the popular lighting fixtures used to complete this request include LED downlight wafers and troffer luminaires. At Tenmat, we have formulated a line of fire-rated enclosures to properly fire rate either an LED downlight or troffer. Understanding that these solutions will need to be placed into a pre-existing ceiling, Tenmat’s Fire Rated Covers for LED downlights and troffer luminaires can easily be retrofitted into the ceiling. To further explore this fire-rated technology, please click here.

Passive Fire Protection for In-Ceiling Loudspeakers.

- As interior ambience and environment become an essential part of modern-day design, implementing in-ceiling loudspeakers have been a common upgrade in commercial spaces. However, the installation of these loudspeakers does expose the integrity of the fire-rated ceiling’s composition. Engineered to be retrofitted into a pre-existing ceiling, Tenmat’s FF109-FRSC 1 Hr. Fire Rated Speaker Cover is tailored to fire rate a wide range of in-ceiling loudspeakers, regardless of manufacturer or model. To learn more about the FF109-FRSC and its additional benefits, please click here.

If you any additional questions about Tenmat’s technology, please feel free to contact us here.

Common Mistakes in Relighting Projects.

With a clear vision on how an individual should proceed when working with passive fire protection in ceilings, it’s time to address some of the common mistakes one can face during installation. One of the most common mistakes during relighting upgrades is failing to maintain the integrity of specified fire-rated solutions. Cutting through fire-resistant ceilings to install new lighting fixtures or in-ceiling loudspeakers often leads to gaps or penetrations that are not properly sealed afterward. This oversight can significantly compromise the compartmentation of a building, allowing smoke and fire to spread more rapidly in an emergency. Contractors may also use incorrect materials for sealing penetrations, such as non-rated sealants, which do not meet fire protection standards. Ensuring that all penetrations are sealed with tested and approved fire-stopping systems is critical to maintaining the fire-resistance rating of the structure. To avoid this common issue, all Tenmat’s Fire-Rated Solutions do not require any additional tools or materials upon installation.

Still and all, there is one last major mistake that curates an improper fire-rated resistance ceiling– specifying improperly fire tested and certified products and materials. Repeatedly, contractors and specifiers have failed to recognize the difference between a solution that holds a proper vs. improper fire rating. For a solution to uphold a proper fire rating, the solution needs to undergo proper testing and certification from an accredited third-party testing facility, such as UL and Intertek. To review a product’s testing and certification, simply visit the manufacturer’s website, and review the solution’s listing, test report, or certification. If you are unable to locate the certification or questioning the authenticity of the certification, you can visit one of the national and international acclaimed independent third-party testing laboratories, such as Underwriter Laboratories (UL) or Intertek, and verify the solution’s testing. If you are unable to find the proper certification, the “fire-rated solution” is not properly fire tested. All of Tenmat’s Fire Rated Covers are properly tested and certified testing laboratories, such as UL and Intertek.

Conclusion

To wrap up this entire article into one statement, passive fire protection is a critical and often overlooked aspect of relighting renovations in existing buildings. As urban infrastructure evolves and renovation projects become more common practice, ensuring the safety of both the structure and its occupants must remain a top priority. Properly specifying and installing fire-rated solutions is essential for preserving the integrity of fire-resistance rated assemblies, particularly in ceiling upgrades that are often subject to unprotected openings caused by recessed lights and in-ceiling loudspeakers. By understanding the importance of both curating a cohesive fire protection system that incorporates both passive and active fire protection, construction professionals can not only comply with current building codes but also enhance the overall safety of redevelopment projects.

Avoiding common mistakes—such as failing to properly seal penetrations, using untested materials, and neglecting to verify fire ratings—can significantly reduce risks and ensure compliance with the latest safety standards. By taking the time to select high-quality, certified fire-rated products, like Tenmat’s Fire Rated Covers, construction teams can streamline the installation process, reduce delays, and ultimately provide greater peace of mind for building occupants. As the industry continues to innovate, combining modern technologies with reliable, passive fire protection will remain a cornerstone in ensuring the safety and longevity of both existing and future buildings.