Learn More About the Ins and Outs of Passive Fire Protection in the Vast Spectrum of Construction Applications.

In today’s construction landscape, construction professionals are constantly experiencing building code adoptions. One of the key reasons for the consistency in building code updates is the advocacy for up-to-date life safety measures for traditional and modern construction applications. Therefore, the use of passive fire protection has become quite popular on active construction sites and new construction infrastructures; however, there are still questions surrounding this form of life hazard. Here at Tenmat, we understand the monetary costs of a failed building inspection and the liability of installing a falsified fire-rated solution. In this blog, we will be answering some of the most important and frequently asked questions regarding passive fire protection. Well, there’s no time to waste when it comes to safety – let’s get started!

“I just failed a building inspection. The electrical inspector stated that my fire-resistance rated ceilings have been compromised, due to installation of recessed can lights. Why is my ceiling compromised? What building codes are associated with this situation? Are there any available solutions?”

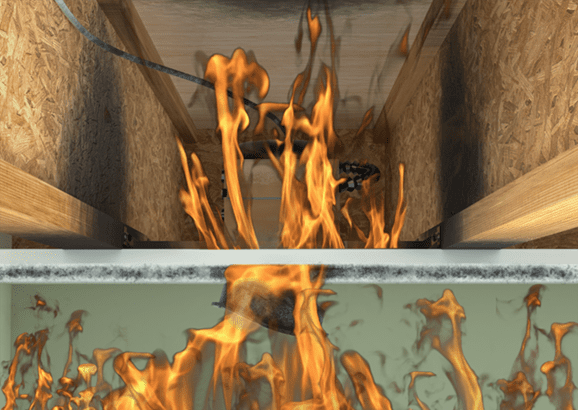

Municipalities across the United States – through adoption of the International Building Code – require fire-resistance-rated ceilings for certain commercial, industrial, institutional, residential, and other occupancies buildings. When a fire-resistance rated ceiling assembly is penetrated by a fixture, such as recessed can light, LED downlight, or troffer luminaire, the ceiling is now compromised. The reason being is when there is a fire outbreak, the flames and heat disintegrate the fixture within several minutes. Once the fixture is non-existent, the ceiling opening no longer works as a barrier to protect flames, heat, and smoke from traveling throughout the rest of the building. As a result, building code professionals have established a requirement for these unprotected ceiling openings. For reference, in section 714.5.2 of the 2021 IBC: “Where floor/ceiling assemblies are required to have a fire-resistance rating, recessed fixtures shall be installed such that the required fire resistance will not be reduced.” To resolve this issue, there are various passive fire protection solutions that accommodate to these life safety hazards, which we will learn more about in this blog.

“I am specifying passive fire protection solutions in a new-construction multifamily complex. I saw various forms of passive fire protection solutions; but I know not all solutions are properly fire-tested. How do I know which solutions are properly fire-tested?”

One of the simplest ways to confirm that a solution is properly fire tested is to visit the manufacturer’s website, and review the solution’s listing, test report, or certification. If you are unable to locate the certification or questioning the authenticity of the certification, you can visit one of the national and international acclaimed independent third-party testing laboratories, such as Underwriter Laboratories (UL) or Intertek, and verify the solution’s testing. If you are unable to find the proper certification, the “fire-rated solution” is not properly fire tested.

“Currently, I am looking for a non-standard passive fire protection solution. How do I accommodate this life safety hazard with the correct passive fire protection solution?”

With the rapid growth of modern construction practices, new life safety hazards spring up on a regular basis. In response, passive fire protection manufacturers are expected to formulate the proper solutions for these hazards; however, modern construction practices are accelerating more rapidly than the evolution of passive fire protection solutions. Here at Tenmat, we understand that all life safety hazards need to be fitted with the proper solution. With our on-site research and development team, we have the accessibility to work one-on-one with construction and building professionals to develop non-standard passive fire protection solutions and test them. Sounds like a current problem you are facing? Contact us at +1-800-821-3436 to learn more about the opportunities Tenmat has to offer you and your team.

“When exploring for passive fire protection solutions, I came across a variety of fire-rated materials. What are the differences between intumescent, mineral wool, fire-rated drywall, and metal solutions?”

With the growing demand for passive fire protection solutions, the availability of different fire-rated materials has significantly increased. One of the traditional firestopping materials is “fire-resistant” gypsum wallboard. This material tends to result in a highly labor-intensive installation, which may increase the cost of installation beyond budget limits. Another commonly used material is metal; however, metal is not very flexible, in terms of aesthetic and product variations. In addition to its lack of flexibility, metal is also known to be a poor insulator and will not sufficiently stop the fire’s heat transfer. In contrast, mineral wool and intumescent are known to be ideal for firestopping applications, due to their flexible nature and their adaptability to produce various forms of firestopping solutions.

Even though the above materials are associated with firestopping capabilities, it DOES NOT mean that the final product offers the same level of firestopping. Therefore, it is critical to review the manufacturer’s testing certification to verify that a solution is properly fire tested.

“I know unprotected ceiling openings caused by recessed lights need to be properly fire-rated. But, what about other recessed fixtures, such as in-ceiling loudspeakers?”

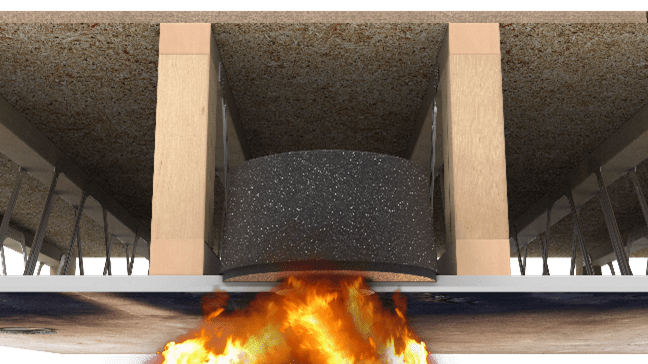

Yes, in-ceiling loudspeakers need to be properly fire-rated in fire-resistance rated ceiling/floor assemblies. In addition to the 2021 IBC Section 714.5.2, the 2017 NEC (National Electrical Code) requires in Section 640.25, “Loudspeakers installed in a fire-resistance rated partition, wall or ceiling shall be listed in an enclosure or recess that maintains the fire resistance rating”. Even though this life safety hazard has been present for several years, there are very few optimal solutions to rectify this hazard. As a direct response to this building code, Tenmat has formulated the optimal fire-rated solution, the FF109-FRSC, a 1 Hour Fire-Rated Speaker Cover. Composed with the latest intumescent technology, the FF109-FRSC has the ability to contain flames, smoke, and heat for 60 minutes – allowing additional time for evacuation of the blazed structure. As an added bonus, the sound absorbing properties of the proprietary intumescent material enhances the acoustic performance and protection of the installed loudspeaker. Learn more about the key benefits of installing Tenmat’s FF109-FRSC by visiting this website.

“I noticed that there a variety of passive fire protection solutions on the market. What are the advantages and disadvantages of each variation of fire-rated solutions?”

There are several different solutions for fire-resistance rated ceiling membrane applications with a diverse range of prices, approvals from third-party testing facilities, and product designs. One of the recent trending solutions are “fire-rated” lights. These solutions are budget-friendly and offer quick, easy installation for on-site contractors. However, a huge misconception about these solutions is because they are composed of metal – they are UL-classified and are suitable for applications where fire-resistance is required. However, this is false. Even though, metal itself, offers some firestopping properties – it is a poor insulator and does not mean that a metal-based solution qualifies as a fire-rated solution. In order for any solution to claim they are fire-rated, it needs to be tested and approved by a third-party laboratory.

One of the more traditional firestopping methods is fire-rated drywall boxes. This firestopping method is where gypsum wallboard surrounds the recessed fixtures; however, there are several cons of this practice. Dry-wall boxes are known to be very labor intensive and may increase the cost of installation beyond budget limits, in addition to possibly not having a proper fire-resistance rating.

Finally, a popular intumescent firestopping solution, which is properly fire-tested by a third-party laboratory (UL and Intertek), are Tenmat’s Fire-Rated Enclosures for in-ceiling fixtures. Tenmat covers are suitable for recessed can lights, LED downlights, troffer luminaires, and in-ceiling loudspeakers – applicable to various sizes and systems. Tenmat Fire Rated Speaker Covers are used in various applications throughout the entire United States and Canada; from multi-residential homes to retail spaces, hospitals, and assisted-living homes. To learn more about Fire Rated Covers, please visit https://www.tenmatusa.com/.

Today, we covered a majority of the most frequently asked questions regarding passive fire protection solutions and their role in the evolving construction landscape. However, we aren’t learning if no additional questions arise. If we didn’t answer your questions today, please feel free to contact one of our on-site specialists at +1 (800) 821-3436 or email us at info@tenmatusa.com.