Discover why unprotected recessed can lights require passive fire protection solutions in multi-family homes.

Life Safety – the main catalyst for the rapid adoption in passive fire protection solutions and materials in the construction landscape. From through-penetration openings to ventilated air cavities, passive fire protection is required in a multitude of applications, environments, structures, and practices.

With the rapid expansion of this demand, passive fire protection specialists, such as Tenmat, have been put to the test in their ability to create the latest innovations in passive fire protection technology while simultaneously meeting the latest in construction practices. Unfortunately, the ever-changing landscape has “dimmed the lights” on certain passive fire protection solutions that aren’t related to the latest building code adoptions. So, let’s get back to the basics – unprotected ceiling openings caused by recessed can lights.

The Origin of Life Safety – Recessed Can Lights

Recessed can lights are commonly installed into the ceilings of both residential and commercial buildings. Often, ceiling/floor assemblies of multi-level buildings must comply with stringent fire regulations, and when necessary, the construction should be fire-rated. But, why?

When recessed lights are specified into these assemblies, the installation of these fixtures creates an unprotected opening. In the event of a fire, the fixture melts aways in minutes. With this opening, heat, smoke, and flames have immediate access to travel from room to room, level to level.

To protect the lives and properties within our communities, the International Building Code addressed in section 714.5.2 of the 2018 IBC:

“Where floor/ceiling assemblies are required to have a fire-resistance rating, recessed fixtures shall be installed such that the required fire resistance will not be reduced.”

With this issue addressed, construction professionals are required to implement appropriate levels of fire protection – especially within ceiling assemblies. Please review the list below of the common applications where these standards may arise:

- Multifamily Communities

- Healthcare Facilities

- Assisted Living and Rehabilitation Centers

- Pre-K and Elementary Schools

- Jr/Sr High Schools

- Higher-Education Institutions

- Student Housing

- Mixed-Use Buildings

The Threats of Tradition

With the newfound demand for a passive fire protection solution and its non-existence, the race to formulate a proper solution commenced. Resulting from this demand, one of the first forms of passive fire protection originated – self-made boxes made out of Type X sheetrock.

Known for its cheap material cost, traditional drywall boxes were ideal to use when resolving the compromised ceilings. However, these solutions had major flaws with their improper fire ratings and costly labor expenses.

For this reason, fire-rated lighting fixtures were introduced. With their ability to fulfill lighting demands and fire protection standards, fire-rated recessed can lights were an optimal solution for both general contractors and electrical contractors. Often, the material costs of a fire-rated light remain at the higher end – not ideal for projects, who have strict budgets.

Due to this, contractors, architects, and developers were still seeking a fire-rated solution, where the solution can fully meet all the following demands:

- Stringent Building Code Standards

- Easy Installation Steps

- Cost-Efficient

In response, Tenmat developed our line of Fire-Rated Covers – specifically formulated for recessed can lights.

Progression in Protection

Composed of intumescent material, Tenmat introduced the FF109-300, and FF109-350 Fire Rated Recessed Light Covers. With its intumescent composition, the cover allows for 60 minutes of protection from heat, flames, and smoke – allowing for additional evacuation time for the building’s occupants. Another added benefit of using intumescent technology is its flexible and lightweight composure. With the ability to be easily installed, our Fire-Rated Solutions have proven to provide significant labor savings, unlike traditional passive fire protection solutions.

Our Fire-Rated Recessed Can Light Covers are able to be paired with a variety of recessed cans, regardless of make and/or model. With this feature, contractors can easily install these solutions into ceiling assemblies, while meeting the overall building’s aesthetics.

To learn more about these products, please visit the following pages:

FF109-300 Fire Rated Recessed Light Cover

FF109-350 Fire Rated Recessed Light Cover

Conclusion

In conclusion, ensuring the safety and integrity of multi-family homes and other structures with recessed lighting is important. The evolution of passive fire protection for recessed cans, such as Tenmat’s Fire-Rated Recessed Light Covers, highlights the importance of addressing unprotected ceiling openings. By integrating advanced intumescent solutions and materials, construction professionals can significantly enhance fire protection, providing crucial evacuation time. As we continue to innovate and adhere to developing building codes, we must remember that the goal is to protect the lives and properties within our communities. Get Active About Passive Fire Protection – Specify Tenmat.

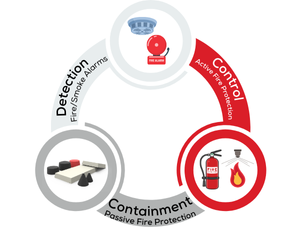

defined as “methods of providing for fire control or fire extinguishment”. As previously stated, there are a variety of moving parts in the definition of fire protection; therefore, it is critical to fully comprehend all of the pieces to the puzzle of fire protection. Fire protection is composed of three different segments: Detection, Control, and Containment. Each of these segments are important independently; however, the cohesion of all three segments are essential when creating an optimal fire protection system. Furthermore, let’s explore deeper on the significance of each pillar’s role in a fire protection system and how they work interconnectedly to protect the lives and properties within our communities.

defined as “methods of providing for fire control or fire extinguishment”. As previously stated, there are a variety of moving parts in the definition of fire protection; therefore, it is critical to fully comprehend all of the pieces to the puzzle of fire protection. Fire protection is composed of three different segments: Detection, Control, and Containment. Each of these segments are important independently; however, the cohesion of all three segments are essential when creating an optimal fire protection system. Furthermore, let’s explore deeper on the significance of each pillar’s role in a fire protection system and how they work interconnectedly to protect the lives and properties within our communities. evacuation period – allowing for occupants to get a head start on exiting the building safely. In addition to the extended evacuation period, these systems alert local first responders about an active fire– permitting a faster response rate to the outbreak. In addition to the previously mentioned key components of Detection, the following:

evacuation period – allowing for occupants to get a head start on exiting the building safely. In addition to the extended evacuation period, these systems alert local first responders about an active fire– permitting a faster response rate to the outbreak. In addition to the previously mentioned key components of Detection, the following:

Formulated to protect openings caused by cables, pipes, or mixed penetrations, the FF260 Fire Protection Block is an optimal solution for a majority of through penetration systems. Composed of a rapidly expanding intumescent foam, the FF260 is able to halt the spread of flames, heat, and smoke for up to 120 minutes. To learn more about this solution, please

Formulated to protect openings caused by cables, pipes, or mixed penetrations, the FF260 Fire Protection Block is an optimal solution for a majority of through penetration systems. Composed of a rapidly expanding intumescent foam, the FF260 is able to halt the spread of flames, heat, and smoke for up to 120 minutes. To learn more about this solution, please UL-Classified. Properly fire rates membrane penetrations in walls and ceiling assemblies. Designed for irregular, hard-to-access, and large penetrations. Meet the FF360 Fire Protection Foam. Tenmat’s FF360 Fire Protection Foam is the optimal firestopping solution for through-penetration applications, due to its composition flexibility, hassle-free installation and proper testing certification for up to 120 minutes. Interested in learning more about this advanced intumescent product?

UL-Classified. Properly fire rates membrane penetrations in walls and ceiling assemblies. Designed for irregular, hard-to-access, and large penetrations. Meet the FF360 Fire Protection Foam. Tenmat’s FF360 Fire Protection Foam is the optimal firestopping solution for through-penetration applications, due to its composition flexibility, hassle-free installation and proper testing certification for up to 120 minutes. Interested in learning more about this advanced intumescent product?  Trying to properly fire rate a small, irregular penetration opening? At Tenmat, we offer a specialized firestopping solution, designed to fire-rate the most irregular and smallest openings, and composed of the latest in intumescent technology. Tenmat’s FF365 Fire Protection Sealant is a red, one-component, gun-grade, intumescent firestop sealant for use in a variety of UL through-penetration firestopping. In addition to its firestopping abilities, the FF365 can be used in combination with other TENMAT products, such as the FF260 Fire Protection Block. To learn about the true capabilities of this fire-rated solution,

Trying to properly fire rate a small, irregular penetration opening? At Tenmat, we offer a specialized firestopping solution, designed to fire-rate the most irregular and smallest openings, and composed of the latest in intumescent technology. Tenmat’s FF365 Fire Protection Sealant is a red, one-component, gun-grade, intumescent firestop sealant for use in a variety of UL through-penetration firestopping. In addition to its firestopping abilities, the FF365 can be used in combination with other TENMAT products, such as the FF260 Fire Protection Block. To learn about the true capabilities of this fire-rated solution,