Intumscent Fireblocking Exceeds Required Fire Performance While Maintaining Rainscreen Principles Needed in High-Performance Walls

Written by Antoine Habellion, P.Eng., M.Eng., M.S. and Steven Gaynor, MBA

Introduction

From the time of Nero’s reconstruction of Rome, fire performance requirements in exterior walls have been a cornerstone of local building codes. Furthermore, the fundamental concepts of fire control have remained unchanged since the inception of mandated fire performance requirements for materials and assemblies: controlling combustible materials, spacing, or compartmentalizing, and imposing height or area limitations.

However, as the science of building and materials has evolved, so too have the complexities of these fire management principles. Today, in American building practices, there are almost no opportunities for avoiding combustible materials all together. Lightweight construction requires the use of membranes, sealants, flashings, etc. With few exceptions, exterior walls must employ the use of combustible materials for at least these conditions. Often, today’s high-performance requirements will also require

the use of combustible materials in other parts of the assembly, where there may be no functionally equal alternatives that are noncombustible; this particularly true for water-resistive and air barriers.

Aiming to enhance the fire safety standards of New York City, the city council approved new requirements for the exterior walls of buildings constructed within

the city. These requirements, passed as part of the approval for the 2022 Construction Codes (New York City Building Code), came into enforcement in late 2022. It was quickly recognized by the building community that the new code language, seemingly inadvertently, ruled out the use of previously accepted ventilated façade

assemblies.

The unintended consequence of virtually eliminating the vast majority of ventilated façade systems is the increased challenge for designers to create exterior walls that effectively manage water over the building’s lifespan, while also providing the thermal performance needed to meet energy requirements like those outlined in the New York City Energy Conservation Code (NYCECC) and NYC’s Local Law 97. It also presents the risk to limit the architectural expression, by significantly reducing the number of options available.

Ventilated facades and the high-performance materials utilized in their construction are critical tools in the design and performance of buildings, ensuring they meet the ever-evolving performance needs of exterior wall assemblies.

For decades, buildings have relied on in- tumescent materials for fire control. These applications range from fireproofing of structural steel, through-penetration firestopping of mechanical and electrical service, perimeter edge sealing of fire doors, to joint and gap sealing of fire compartments to limit fire spread from one part of a building to another.

These materials have also been used in the exterior cavities of façades assemblies for the same compartmentation purposes globally for over two decades. However, they are currently not included in the list of fireblocking materials prescribed in the New York City Building Code.

These materials have also been used in the exterior cavities of façades assemblies for the same compartmentation purposes globally for over two decades. However, they are currently not included in the list of fireblocking materials prescribed in the New York City Building Code.

Intumescent materials, which expand when heated, provide a critical barrier against heat and flame during fire events. These materials have not only proven to be an effective fire- blocking solution, but tests have demonstrated that they can also outperform traditionally accepted materials in aspects crucial to containment.

This paper posits that intumescent fireblocking is a simple, safe, and effective fireblocking material that may, right now, be the only tested option which can provide the intended protection during a fire event and maintain rainscreen principles continuously throughout the exterior wall covering. Simultaneously, it enables the design of exterior walls that can meet the other stringent performance requirements imposed on today’s buildings.

Background on NYC Fireblocking Requirements

In November 2021, New York City became the first jurisdiction in the United States to pass building code requirements with an expansive mandating for the use of fireblocking in the exterior cavity of ventilated façade assemblies. These are assemblies that include an exterior cavity between the thermal barrier and the cladding, also known as rainscreens, one of the most common assemblies that include ventilated exterior cavities.

While NYC may have escalated the fireblocking requirements, those familiar with the Interational Building Code (IBC) will know that these requirements are not new. All interior spaces are mandated to have some degree of compartmentalization to hinder fire from spreading from one area to another, typically between units, occupancy types, egress routes, etc.

Exterior cavities, the spaces created between the cladding and the backup wall, have had established requirements for several decades. These IBC requirements date back to its inception, as evidenced by section 716.2.6 from the 2000 IBC.

Enforcement of these requirements has varied widely, but most jurisdictions regularly waived these requirements when an assembly complied with NFPA 285. (National Fire Protection Association’s Standard Fire Test Method for Evaluation of Fire Propagation Characteristics of Exterior Wall Assemblies Containing Combustible Components).

What is the NFPA 285 Testing Requirement?

As the name suggests, NFPA 285 is a test method that provides insight into the actual performance of a specific wall assembly—in- dividual specific components combined in a particular geometry—when exposed to conditions akin to an actual structure fire.

NFPA 285 uses a multistory wall assembly subjected to actual fire temperatures expected during an event. Originating from a larger test (UBC 17-6), it was reduced to its current size of roughly 18’ tall after addition- al testing revealed that the large size tests produced the same results as the 18’ test. This consistency increased our confidence that we are witnessing genuine performance when testing according to NFPA 285. There- fore, while it is important to note that NFPA 285 is still a qualifying test, which does not simulate every building condition, a successful NFPA 285 test others a high level of confidence in the safety of the assembly during a fire event.

With NFPA 285 providing insight into the actual flame propagation of an assembly (measured both inside the exterior cavity and on the face of the cladding), building officials often felt confident waiving the fire- blocking requirements if the correlating test was performed without fireblocking.

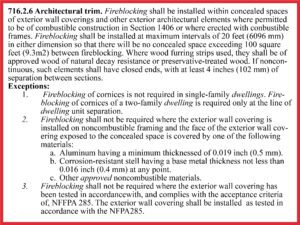

This reasoning was adopted by the International Code Consortium into the code language for the 2012 IBC, by adding exception 3 to the relevant fireblocking section (See excerpt below).

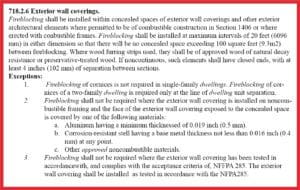

When is fireblocking required in the exterior cavity for the IBC?

As per the language in IBC 2021 (the cur- rent version as of this writing), fireblocking of the exterior cavity is required in ventilated façades when either the cladding or the framing materials are combustible, and the assembly hasn’t been tested to comply with NFPA 285. Generally, NFPA 285 is deemed applicable for cladding and components when a building’s elevation exceeds 40 feet. This means there’s a high likelihood that projects need to comply with fireblocking requirements on buildings under 40 feet that contain combustible cladding or attachments, wherever this IBC language is adopted.

While there are a few exceptions, and every project should be reviewed by a qualified professional, this rule of thumb helps us identify the buildings most likely to require fireblocking.

When this requirement does apply, designers and suppliers have limited options. The first is to install an assembly that has been tested in accordance with NFPA 285. As previously mentioned, this is a large and expensive test, which only applies specifically to those materials that have been tested in the same combination and geometry as what was installed on the test. The second option is to add fireblocking, but the available materials accepted for fireblocking are also limited.

Fireblocking materials are listed in the IBC. This list (shown below) contains materials that are used for all fireblocking requirements. Notably, most materials listed are not suitable for exterior use, especially in ventilated exterior cladding assemblies which may or may not have open joints.

What is different with the 2022 NYC Construction Code?

Importantly, we must first recognize that NYC has a history of significant variations from the model codes in the US. Until 2008, NYC created and maintained its own building code. While these new requirements might be a major upheaval for our industry, the process for getting here was quite unextraordinary. It is best to view this as a scheduled cyclical update following a mundane bureaucratic process. A task group is coordinated to review model code language and decide how to adopt it for NYC. In this particular revision cycle however, the task group developed new language that was not related to model code changes.

Considering the acceleration of the construction of high-rise buildings in NYC, and the fire events experienced in other countries, the code committee in NYC seemingly wanted to increase the robustness of the fire requirements for exterior assemblies.

They attempted to do this through rewriting several sections of the building code having to do with both the fire performance requirements of exterior walls and fireblocking requirements. These include, material combustibility requirements (ASTM E136), classification requirements (ASTM E84), propagation requirements (NFPA 285), and ratings requirements (ASTM E119).

While there is debate about whether the effect of these requirements meets the intent of adopting them, the effort to build confidence in fire performance of US buildings has been a renewed focus for building officials across the country for the past two decades.

The fireblocking requirements (Section 718.2.6) are the focus of this paper and NYC has explicitly intertwined those requirements with the NFPA 285 requirements (Chapters 14 and 26)

Through these changes, NYC mandated that any assembly which required both fireblocking and testing according to the NFPA 285 standard will now require the submission of a test report that includes fireblocking.

In practice this vastly expanded the requirements for fireblocking in rainscreens and other assemblies while also requiring an NFPA 285 test to be performed specifically to the NYC requirements.

The industry is currently woefully underprepared to comply with such a stringent new requirement.

Art Parker, Principal Fire Protection Engineer, RDT&E, estimates that less than 2% of existing NFPA 285 test reports can comply with the current NYC language.

He speculates that testing to demonstrate compliance with the new fireblocking requirements in the 2022 NYC Construction Code has started, but it is still in the initial stages. As more projects are being submitted to the NYC Department of Buildings (DOB), the requirements will become more clear and almost every manufacturer will need to consider conducting testing to demonstrate compliance with these new requirements.

“On a parallel path, I expect the NFPA Fire Test Commitee, which is responsible for maintaining and updating NFPA 285, will start to look at what modifications to the standard test set-up and conduct can be incorporated to address evaluating exterior wall assemblies containing fireblocking systems and technologies. Sufficient testing data and experience will need to be developed along with consensus among the committee before we can start to propose changes to the existing testing standard to include fireblocking into test wall assemblies”. Art said referring to the committee he chairs for NFPA.

The average preparation for such a test can take anywhere from 6 to 12 months, from the decision to conduct one, to the final report; not including the wait for an opening in the laboratory schedule. Although expensive and time consuming, project specific testing will likely be needed while the industry has time to catch up with these new requirements.

When is fireblocking required in the exterior cavity with the 2022 NYC Construction Code?

The fireblocking language adopted for the 2022 NYC Building Code might appear subtly different than the IBC at first glance. NYC does maintain the general fireblocking requirements and some of the exceptions of the IBC. However, there are a few wording changes that have monumental impact.

Where NYC fireblocking starts to differ is the elimination of two exceptions listed in the IBC version.

1. NYC eliminated the longstanding Exception 2.3 “Other approved noncombustibles”. By striking this section, NYC eliminates a widely used exception

for materials that qualify as noncombustible. Materials such as porcelain, glass, fiber cement, GFRC, and other noncombustibles now are required to use fireblocking when installed over a combustible WRB.

2. NYC chose not to adopt the 2012 exception that affirmed the common practice of accepting a successful NFPA 285 test assembly without the use of fireblocking.

These two changes alone encompass the majority of the rift between the intent of the 2022 NYC Construction Code and the IBC. When compared to just the existing code language, they suggest that fireblocking in NYC buildings will be required for most materials, and all locations.

There are a few exceptions specific to certain thicknesses of brick, terracotta, stucco, concrete, aluminum, and steel; this implies that fireblocking is required for all combustibles, and those noncombustibles not specifically listed in the exception when used with a combustible water-resistive barrier.

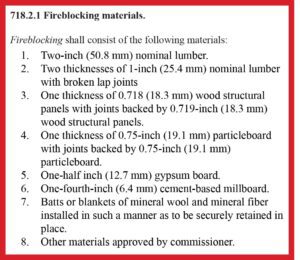

What materials can be used for fireblocking?

Understanding that NYC now requires fire- blocking for most rainscreen and cavity assemblies, there is still an open question about the materials to use. Fortunately (and unfortunately), the NYC code generally matches the IBC list here. (See Figures below)

The material discussion is significant, but first there is a small and possibly critical change to the wording here: the last item of the IBC list is “other approved materials”, which has been changed to “Other materials approved by the commissioner” in the NYC code. Discussions with experts and building officials in NYC have concluded that this language is most likely intended to eliminate opportunities for third party listing and approvals to solely satisfy this requirement. This results in any alternative materials being required to go through the NYC Department of Building approval processes, rather than just submitting an evaluation report from one of the major accredited certifying institutions, which most often satisfies the IBC requirement.

Looking at the approved materials list, it quickly becomes clear that these listed materials are not all appropriate for the exterior cavity, where the material will be exposed to exterior conditions. Filtering out the list, one can conceivably narrow it down to cement board and mineral wool being the only suit- able materials for an exterior environment that will intermittently experience heavy wetting and drying cycles. Thinking through this a little further, using cement board be- tween all of the supports and panel geometries seems completely untenable from an installation perspective, so mineral wool may really be the only constructable option for use as fireblocking in exterior cavities.

Using Mineral Wool as Rainscreen Fireblocking

For anyone who has ever installed one of these exterior cladding systems, mineral wool seems like an easy solution. It is relatively easy to cut, can be compressed for tight fitting, and will likely last for the life of the building.

Using precisely cut blocks of mineral wool installed at intervals to compartmentalize the wall can create an effective barrier for heat and flames. The compartments created with mineral wool are likely to reduce the spread of flames in the cavity. However, fire is just one consideration when building an exterior wall.

Using precisely cut blocks of mineral wool installed at intervals to compartmentalize the wall can create an effective barrier for heat and flames. The compartments created with mineral wool are likely to reduce the spread of flames in the cavity. However, fire is just one consideration when building an exterior wall.

Designing a high-performance building envelope becomes especially challenging in regions like the northeastern US, which experience freezing winters and hot humid summers, where ventilated cladding

assemblies, or rainscreens, have successfully demonstrated that they were effective solutions to address this challenge.

The cavity created by the cladding attachment system serves multiple purposes:

• It allows for the passive removal of liquid water and water vapor.

• It accommodates the use of exterior insulation, which is more thermally effective than insulation placed be- tween wall studs, due to the reduction of thermal bridging effect caused by the studs; it is a simple way to increase the thermal efficiency of the entire wall assembly. It also allows to maintain the temperature of the sheathing above the dew point temperature during the heating season, reducing the risk for moisture related issues.

• It reduces the solar heat gain during summer: the cavity allows the heat to dissipate through ventilation as the sun heats the panels. Blocking this cavity could result in heat build- up and subsequent transfer into the building during the warmer months.

However, the introduction of permanent barriers installed for fireblocking could negate many of the benefits achieved with rainscreen design. This is mainly due to the installation of fireblocking design.

To the obvious question of whether miner- al wool is appropriate for this application, Antoine Habellion, technical director at ROCKWOOL, and who is an expert in thermal performance of the building envelope, and specialized in the use of mineral wool in applications such as rainscreen systems responded that: “there is no obvious rea- son to believe that a mineral wool product could not stay in place and act as an effective fire barrier in a typical rainscreen system for some time, but the use of such product, alone and unprotected, to obstruct the cavity between the cladding and the inner layers of the wall could raise concerns regarding the durability of the product and the overall hygrothermal performance of the wall.

This is because if the mineral wool is block- ing the cavity, it may reduce the air flow within it and therefore slowdown the passive removal of water vapor, potentially resulting in an increase of the risk for moisture related issues, especially with certain cladding type which are more sensitive to moisture. If the cavity is blocked, any water in the cavity may also be forced to drain through the mineral wool, which could act as a filter for dirt, debris, and other contaminants that water is carrying down the cavity. Overtime, the accumulation of organic maters within the wool and the prolonged exposure to wetting and freeze-thaw cycles could promote the development of mold and other fungi, and significantly impact the physical integrity of the mineral wool, potentially jeopardizing its ability to act as an effective fireblocking material.”

Reviewing the approved materials list again, obviously mineral wool still seems the only realistic fireblocking option. However, there are now other challenges to consider. This makes detailing a critical issue in fireblocking design.

How to ensure proper water management with permanent fireblocking

Installation of a permanent, durable, and resilient fireblocking intended to perform for the life of the building, presents many challenges for rainscreen assemblies. Installation of flashing above the fireblocking appears to be a plausible solution. Afterall, flashing is used for interfaces and transitions all over the building.

While it doesn’t completely rectify airflow problems, it can effectively redirect water away from the backup wall and out to the face of the exterior cladding, thus addressing a major part of the concern.

While it is crucial to remember that this approach isn’t the most ideal and may pose challenges in design and installation, it is useful to explore this as a possible path for achieving compliance.

In this case, we would employ a simple rule: if there is fireblocking, there must also be flashing. Where horizontal fireblocking is required, flashing would exist continuously above the fireblocking. Where there is vertical fireblocking, any horizontal terminations should be flashed to redirect water.

The following key features are necessary for this solution:

1. Continuity of flashing: this is vital to ensure that moisture is directed out of the system, and not through the fire- blocking below.

2. Full extension of flashing: it should reach all the way back to the water control layer, through the insulation, and probably to the sheathing.

3. Outward extension of flashing: the flashing must reach out to the face of the exterior cladding to allow for redi- rected water to drain to the exterior.

4. Panel joint design: Joints may need to be designed or widened specifically for this purpose.

5. Hydrothermally inert panel material: This is crucial to prevent warping and bowing of the panels in direct contact with the fireblocking, which could lead to cladding failure over time.

If we take each of these considerations into account, we can create an effective fire- blocking solution that significantly mitigates much of the concern around liquid water.

Putting aside constructability and cost of installation for now, we immediately run into another performance issue; the decrease in thermal efficiency of the exterior wall due to the continuous thermal bridge created by the addition of flashing.

NYC Local Law 97: Actual Performance Matters

New York City’s Local Law 97 represents a shift in focus from the prescriptive require- ments of the IECC towards actual energy use of a building. This law holds building owners accountable for excessive energy use, regardless of the cause. This structure swiftly bypasses the prescriptice account- ing of thermal bridges, rather focusing on measured performance. Building owners are now gettng taxed on their actual carbon use, including energy used by the HVAC systems.

One might imagine building owners will be paying more atention to the actual ther- mal performance of their exterior walls as the checks they have to write continue to increase. Gone are the days of dismissing certain details because the standard doesn’t require it.

As a result, architects and engineers in NYC must consider the impact of every penetration when predicting the actual effective thermal performance of the wall.

Eliot Benor, Testing Manager of Building Envelope Testing LLC, says that he is seeing an uptick in interest for building owners of new and existing buildings to determine exactly what that exterior wall insulation performance actually is.

“This isn’t even just about getting the best designed walls; owners are contacting us to figure out exactly what the thermal performance is of the wall once it is built.

We go to jobsites and existing buildings and provide an assessment of the ‘as built’ condition using specialized equipment.

Owners want to know if they are in for a surprise… most often, not a good one…”

Eliot also points out a critical component to this new law.: there is an unknown when it comes to performance, even with good de- sign.

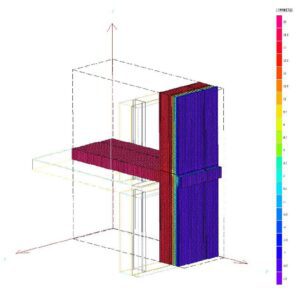

Based on these considerations and using a PC-program designed to perform three-dimensional steady-state heat conduction modelling, Antoine completed a thermal analysis of a typical opaque wall section, with and without the flashing that would accompany a permanent mineral wool fireblocking, to assess the impact of a continuous metal flashing at each floor on the effective thermal performance of the assembly.

With this basic example which included an R-17 (ft².°F.hr)/BTU exterior mineral wool insulation, a 6.0” x 8.0” continuous mineral wool fireblocking at every floor, every 10 feet,

and a 16Ga. flashing angle, he found that the added flashing would result in a degradation of about 10% of the overall thermal performance of the wall if the flashing is made of stainless-steel, and of about 16% if the flashing is made of galvanized steel.

In this example, it was calculated that in order to match the thermal performance of the wall without the flashing, the insulation thickness installed on the clear field of the wall needed to be increased by ½” if the flashing is made of stainless-steel, and by 1.0” if the flashing is made of galvanized steel.

There is a cost to the material and installation of extra inches of insulation, but anyone who has worked in NYC construction knows that fractions of inches around lot lines, and floor space requirements, can force a rede- sign of the entire wall system.

The addition of these constraints emphasizes a need for thoughtful, comprehensive design solutions that consider not only fire safety, but also energy efficiency and sustainability. Achieving a balance between these sometimes conflicting requirements is a challenge that architects, engineers, and building designers must rise to meet.

Bringing It All Together

The DOB is currently reviewing (or at least spot checking) section details for buildings, flagging thermal bridges, and then requiring performance testing for compliance before issuing work permits.

If designers and engineers are mandated to ensure that their buildings do not exceed a specific energy usage target, as seen in NYC and potentially other jurisdictions adopting similar legislation, then any prescriptive code compliance becomes ineffective. The traditional rules allowing designers and engineers to disregard specific reductions caused by peripheral components are no longer relevant. What maters now is the building’s actual performance during operation. The NYC government will be monitoring these buildings and issuing fines to those owners whose properties fail to meet the standard, regardless of the reasons behind the failure. The major conflict be- tween fireblocking requirements in exterior cavities and energy code requirements should now be evident. Designers must con- sider the impact of the actual performance of a wall system on a building’s energy us- age. This consideration includes:

• Continuous thermal bridging at every floor line, opening, and between different types of occupancy,

• A likely decrease in the expected insu- lation value due to the cycles of wet- ting and contamination that lead to slower dryiing of exterior insulation,

• Possible decreased rate of drying from the reduced efficiency of the cavity to evacuate liquid water and vapor from wetted materials.

No designer will want to risk the financial and commercial repercussions that come with failing to meet these performance tar- gets due to unforeseen decreases in energy performance associated with incorporating fireblocking into a ventilated façade assembly.

This situation leaves designers and engineers with a limited range of materials and methods to address non-fire performance requirements. If NYC is committed to up- holding and enforcing the fireblocking requirements in their 2022 Construction Code, alternative approaches must be considered.

Fire Protection Systems: Active vs Passive

Luckily, alternative approaches exist, which allow designers to keep using the proven advantages of ventilated rainscreen assemblies with exterior insulation and continuous, open, exterior cavities to allow for effective drainage of liquid water and ventilation for drying and evacuation of water vapor. The definitions of active and passive fire protection systems are well-defined within the fire protection community. These definitions may not be intuitive, especially when dis- cussing materials that change form during a fire, as part of their protection attributes.

Active fire protection systems need a per- son, trigger, or sensor to “turn it on”. Examples are fire suppression systems like sprinklers or magnetic release of fire doors along egress routes.

Passive fire protection systems don’t require intervention to protect or activate. Examples of these are static systems like firestopping sealants sealing compartments around a conduit, or dynamic systems like intumescent coatings around structural steel that change form and expands during a fire event to protect the steel from dangerous temperatures.

These systems also exist for the exterior cavity; in fact, passive, dynamic fire protection systems are also widely used for compartmentalization of these cavities.

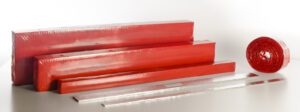

Companies like Tenmat, HILTI, Promat, 3M, and others, all other intumescent-based products that are designed and engineered to be used in the exterior cavity.

Intumescents expand and change form in the presence of heat, like in a fire. This property makes them exceptionally effective and efficient as a fire protection system.

People within the industry will most commonly recognize the term intumescent with coatings often used to protect steel and supports. (See figure below)

In a fire event, the intumescent coating can expand even up to 50 times its original thickness. This creates a protective outer layer that insulates the steel after activation, and greatly reduces the transfer of potentially dangerous heat to that steel.

Intumescent Fireblocking

Intumescents have been utilized for close to 50 years, to contain fire and compartmental- ize units within buildings. The requirements for interior fireblocking and firestopping are well-established and have demonstrated efficacy in slowing the progression of fires throughout a building.

Fireblocking within a building can be created in a variety of ways using different materials. Intumescents are deployed in those loca- tions where open access or open joints need to be maintained between fire compartment units for standard operation of the building but must be sealed off to ensure compart- mentalization in a fire event. Examples of where intumescents are employed include fireproofing of structural steel with intumescent paints or coatings, through-penetration firestopping of mechanical and electrical services such as pipes and cables, perimeter edge sealing of fire doors, and joint and gap sealing of movement joints between building elements forming fire compartments.

In the European Union, the UK, and other parts of the world, these materials are used within the exterior envelopes of buildings. For instance, rigid intumescent strips have been effectively used as fireblocking in the exterior cavities of rainscreen facades since the early part of this century.

How are Intumescents Used in Exterior Cavities?

The intumescent materials used within the exterior cavity of rainscreen facades differ significantly from intumescent coatings used for steel in that they must be capable of spanning and sealing across much larger “air gaps” of typically one to two inches.

Rigid intumescent strips typically utilize expandable graphite which offers greater expansion capabilities, that enable the strip to expand unidirectionally across the air gap and form a resilient flame and heat resisting seal to prevent the fire spread.

Intumescent material is installed in the same locations and compartment sizes as required by other fireblocking materials. Depending on the required cavity depth and adjacent materials, the intumescent material may be installed on a noncombustible carrier or as a standalone material. The method will de- pend on the application and intent of performance.

Testing has shown that intumescents per- form the same or better than traditional fire- blocking materials when used in the exact same locations, geometry, and thicknesses as materials that impede rainscreen, drain- age, and ventilation performance.

These materials are also installed in very similar ways, using fasteners to attach the assembly to the backup-wall. In this way, no maintenance is required. Intumescents can remain in place, ready to perform for the life of a building. They are designed to withstand the exposure to the element expected with this application.

Intumescent Performance

The acceptance of any fire safety product must start with the performance of that product in a fire event. As challenging as it might be to construct a rainscreen without intumescent fireblocking, that is not a valid reason to accept any alternative with lower performance. Intumescent materials have been demonstrated to meet, and in some instances, exceed the performance expecta- tions of approved fireblocking materials.

Intumescent materials have been used in rainscreens for a long time, all over the world. Many manufacturers have used intu- mescent fireblocking in successful NFPA 285 testing. Intumescents have been success- fully used in testing with cladding materials like Aluminum Composite Panels (ACM), High-Pressure Laminates (HPL), and others, where ventilation cavities and open joint systems are critical to overall performance and durability of

the assembly.

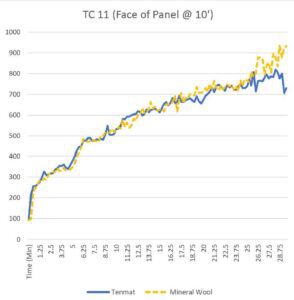

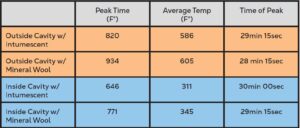

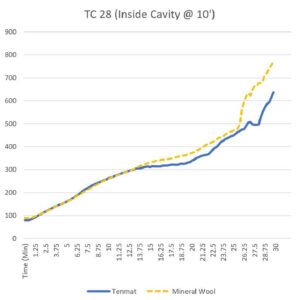

Tests have shown that performance of intumescent fireblocking matches those mate- rials listed in the building code. As an ex- ample, the data below displays heat curves from two comparison NFPA 285 screening tests.

They use exactly the same assembly com- ponents and geometry. The key difference is that one uses mineral wool fireblocking, and the other uses intumescent fireblocking (by Tenmat).

The data shows the heat curves at critical locations in the NFPA 285 test assembly. This is the 10-foot mark, above the window. The first graph shows the heat inside the cavity, and the second graph shows the heat outside the system, on the face of the panels.

For these tests, an ACM panel was used for the cladding panel, the substructure was constructed of a typical aluminum clip and rail system, the water resistive barrier is the same popular self-adhered sheet mem- brane, and both systems used 2” of mineral wool insulation.

The fireblocking location and layout was exactly the same on both tests; around the window, horizontally 32” above the window, and horizontally 142” above the window. See Pictures labeled “TEST 1: Intumescent” and “Test 2: Mineral Wool”. The layout was de- signed to address the requirements in the new 2022 Construction Code in NYC. The difference was the material assembly of the fireblocking.

Test #1 used 4.5 lb/ft² mineral wool as the fireblocking material. This material is under the “fireblocking materials” list in 718.2.1 . It was designed to completely close off the cavity that remained from the back of the ACM panel to the face of the (mineral wool) insulation layer. During installation, the mineral wool was cut and sliced to tightly fit around the cladding attachment system.

Test #2 used Tenmat FF102.50 as the fire- blocking material. The material was used in the same locations and widths as the mineral wool in Test #1. Tenmat fireblocking was placed within 1.5” of the back of the ACM panel leaving approximately that much air- space for ventilation and drainage prior to a fire event.

As mentioned previously, the temperature results for the thermal couples placed in- side and outside the cavity at 10 feet above the window are strikingly similar. The intumescent maintained slightly lower peak and average temperatures, which was consistent with an additional full-scale test also per- formed with the identical assembly.

These side-by-side test comparisons are similar to other large-scale tests performed with intumescent fireblocking and other exterior cladding assemblies.

Conclusion

Many jurisdictions in the US are looking closely at the fire performance requirements of exterior wall covering assemblies. The model codes, and most jurisdictions contain restrictive guidelines for fire performance that, when properly followed, have impressive safety records.

There exists fireblocking requirements for some applications in model codes and local jurisdictions that require the compartmentalization of the cavity created in the exterior wall covering. Where applicable, these requirements often conflict with proper water, air, and thermal management, and some- times with other building code requirements, forcing architects and engineers to redesign the wall, often with lower performance, less desirable materials, and

assemblies.

Using a fireblocking that will remain open during normal operation, then seal the cavity when a fire event occurs is the only practical way to address both the fire concerns and the most advanced building practices using high-performance materials and assemblies, like rainscreens.

Intumescent have a proven performance in these applications with a long history around the world. In the US, some product manufacturers have tested intumescent materials as an exterior wall covering fireblocking option since the mid 2000’s.

The results displayed in this paper indicate that intumescent fireblocking could produce the similar or better performance, using the same fireblocking layout and dimensions as traditional fireblocking materials, while maintaining crucial healthy building practices associated with water management, ventilation, air management, and thermal performance during normal operation. Jurisdictions in the US have been slow to accept these solutions, but increased fire performance requirements are going to require the American construction community to find new ways to satisfy competing demands.

References

1. Murariu, M., Laoutid, F., Dubois, Ph., Fontaine, G., Bourbigot, S., Devaux, E., Campagne, C., Ferreira, M., & Solarski,

S. (2014). Pathways to Biodegradable Flame Retardant Polymer (Nano)Composites. In C. D. Papaspyrides & P. Kiliaris (Eds.), Polymer Green Flame Retardants (pp. 709-779). Elsevier.

2. Offshore-technology.com. (2009). Puttng Energy into Coatings. Retrieved May 4, 2023, from htps://www.offshore-

technology.com/features/feature68802/

3. American Society of Heating, Refriger- ating and Air-Conditioning Engineers. (2022). Standard 90.1: Energy Stan- dard for Buildings Except Low-Rise Residential Buildings.

4. ASTM International. (2022). ASTM E 136 Standard Test Method for

Assessing Combustibility of Materials. ASTM International.

5. City of New York. (2022). NYC Construc- tion Code: 2022 Edition. New York De- partment of Buildings.

6. International Code Council. (2021). International Building Code: 2021 Edition. ICC.

7. International Code Council. (2021). International Energy Conservation Code. ICC.

8. National Fire Protection Association. (2023). NFPA 285: Standard Fire Test Method for Evaluation of Fire Propagation Characteristics of Exterior Non-Load-Bearing Wall Assemblies Containing Combustible Components. NFPA.

9. Straube, J. (2012). High Performance Enclosures. Building Science Press.

10. The American Institute of Architects. (2014). The AIA Handbook of Architec- tural Practice (15th ed.). The American Institute of Architects.

11. Tenmat, Inc. (Year). FF102.50 Data Sheet. Retrieved from htps://www.tenmat.com/wp-content/ uploads/FF102-50-datasheet-v1- 22.3.pdf

12. New York City Council. (2019). Local Law 97 of the City of New York. Retrieved from htps://www.nyc.gov/assets/buildings/local_laws/ll97of2019.pdf

13. Tacitus. (c. 109 AD). Annals.

14. Beard, M. (2015). SPQR: A History of Ancient Rome. Profile Books.

15. Stambaugh, J. E. (1988). The Ancient Roman City. Johns Hopkins University Press.

16. Tacitus, C. (1939). The Annals of Tacitus, book XV, Section 43. Methuen & Co. Ltd.