The Importance of Implementing Passive Fire Protection in Audio Applications

From high-definition displays to immersive sound systems, A/V technology remains a driving force in reshaping our community’s entertainment and communication landscape. The A/V industry presents an extensive array of technologies, encompassing gaming consoles, video projectors, televisions, and much more. However, in this discussion, we will focus on one of the most popular A/V solutions: in-ceiling loudspeakers. In-ceiling loudspeakers seamlessly integrate into various construction practices, finding their place in residential home cinemas, shopping malls, office buildings, university lecture halls, and a wide range of diverse applications.

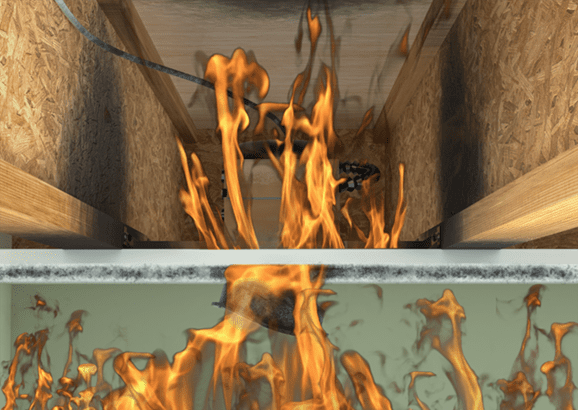

Whether you are installing recessed speakers in your local high school’s new auditorium or upgrading your at-home theater, it is important to acknowledge the safety hazard of installing these products into various ceiling structures. Once installed in a fire-resistance rated ceiling assembly, the integrity of the ceiling has been compromised. If these openings remain unprotected, flames, smoke, and heat will be able to spread at a rapid rate, putting lives and property at risk. As a result, passive fire protection measures have been implemented through various building code requirements – requiring contractors to install a fire–rated solution or housing to contain the fire for a long time.

In addition to this requirement, when installing in-ceiling loudspeakers, you also may need to be concerned about the sound dampening capabilities of the fire-rated solution. In states, such as California, have adopted a minimum level of sound isolation across party walls and floor/ceiling in hotels, condominiums, dormitories, office buildings, and multi-family complexes. Therefore, developing a solution that can meet both building requirements is ideal for labor and cost savings.

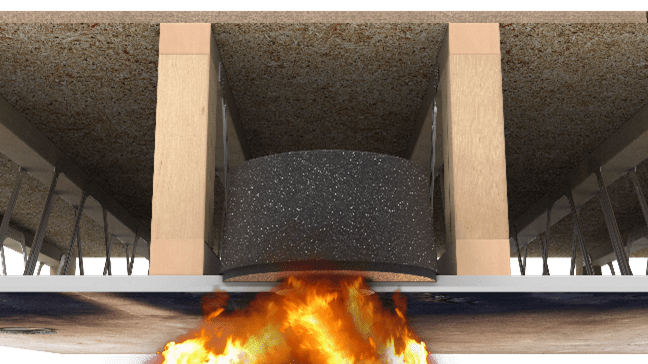

At Tenmat, we are committed to developing the latest fireblocking technology and catering to the demands of A/V installers and electrical contractors. A blend of sound isolation, easy installation, and passive fire protection, TENMAT created the FF109-FRSC, a one-hour fire rated speaker cover. The FF109-FRSC 1 Hour Fire Rated Speaker is a dome-shaped intumescent enclosure which has been specifically designed to help maintain the integrity of fire-resistance rated ceiling/floor assemblies for one hour when penetrated by in-ceiling speakers. In addition, the sound absorbing properties of the propitiatory intumescent material enhance the acoustic performance of the speaker’s housing – allowing for a level of sound isolation.

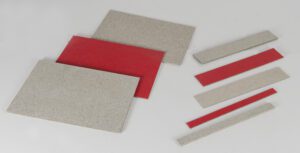

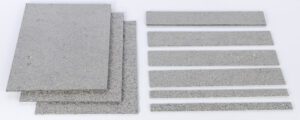

With its adaptability and flexibility, Tenmat’s intumescent materials offer fireblocking and sound isolation properties to a multitude of applications. Our manufacturing capabilities allow us to cater to the most forward-looking applications. With its fire protection feature, Tenmat’s intumescent materials have the capability to fire-rate a pre-made audio design, such as an intumescent insert in a speaker’s housing, in shape of a disc, square, gasket or box. In addition to its fire protection capabilities, Tenmat’s intumescent materials can cater to sound isolation applications – such as multi-family complexes, sound rooms, choir rooms, and so much more.

As the demand for firestopping solutions rises, many “fire-rated” solutions have entered the market. However, it is important to remain vigilant on the fire testing approvals of these numerous solutions. For a product to be fire-rated, it must have an ETL or UL Classified Testing and Approval certification. At Tenmat, all our fireblocking materials and solutions have an ETL or UL Classified listing, which can be easily located on our website.

If you are interested in learning more about the key benefits of installing Tenmat’s innovative intumescent technology, please visit https://www.tenmatusa.com/frsc/.